Introduction

Amid the rapid growth of the lighting industry, extruded aluminum profiles have emerged as a critical enabler, leveraging their exceptional properties to revolutionize every stage of luminaire manufacturing. From heat dissipation to structural integrity and design versatility, these profiles are reshaping how lighting systems are engineered and deployed across diverse applications.

1. Core Application: Light Fixture Housings

Extruded aluminum profiles serve as the “guardians” of lighting systems, with their outstanding thermal management capabilities. The superior thermal conductivity of aluminum rapidly dissipates heat generated internally, lowering operating temperatures, extending fixture lifespans, and enhancing lighting efficiency. For example, in high-power LED streetlights, aluminum extrusion housings ensure stable, long-term operation even under extreme thermal loads.

Beyond thermal performance, aluminum profiles combine lightweight construction with high strength, simplifying installation and maintenance while resisting external impacts. In outdoor pendant lights and large commercial fixtures, they provide robust structural support. Additionally, the extrusion process enables unparalleled design flexibility, allowing profiles to be shaped into circular, square, or custom geometries—unlocking limitless creative possibilities for luminaire aesthetics.

2. Precision in Reflector Applications

Extruded aluminum profiles excel as reflectors when paired with advanced surface treatments. Their high reflectivity maximizes light output efficiency, directing beams with precision. In spotlights and track lighting, aluminum reflectors concentrate light onto targeted areas, enhancing illumination quality. By precisely controlling profile shapes and surface curvature, manufacturers achieve tailored reflection angles to meet specific lighting requirements.

For instance, in museum display lighting, aluminum reflectors project light accurately onto artifacts, highlighting textures and details while creating optimal viewing atmospheres.

3. Structural Excellence: Lamp Frames and Poles

In outdoor lighting systems, extruded aluminum profiles provide critical structural support. Their high strength-to-weight ratio ensures stability under wind loads and mechanical stresses, making them ideal for streetlights, plaza lamps, and other heavy-duty applications.

The inherent corrosion resistance of aluminum makes these profiles indispensable in harsh environments. Coastal or humid settings demand materials that withstand moisture, salt spray, and chemicals—a challenge where aluminum lamp poles and frames excel, significantly reducing maintenance costs and replacement frequency.

Surface treatments like anodizing and powder coating further enhance durability while offering aesthetic customization. These finishes improve wear resistance, weatherproofing, and visual harmony with surroundings, elevating both functionality and landscape design.

4. Extended Applications in Lighting Systems

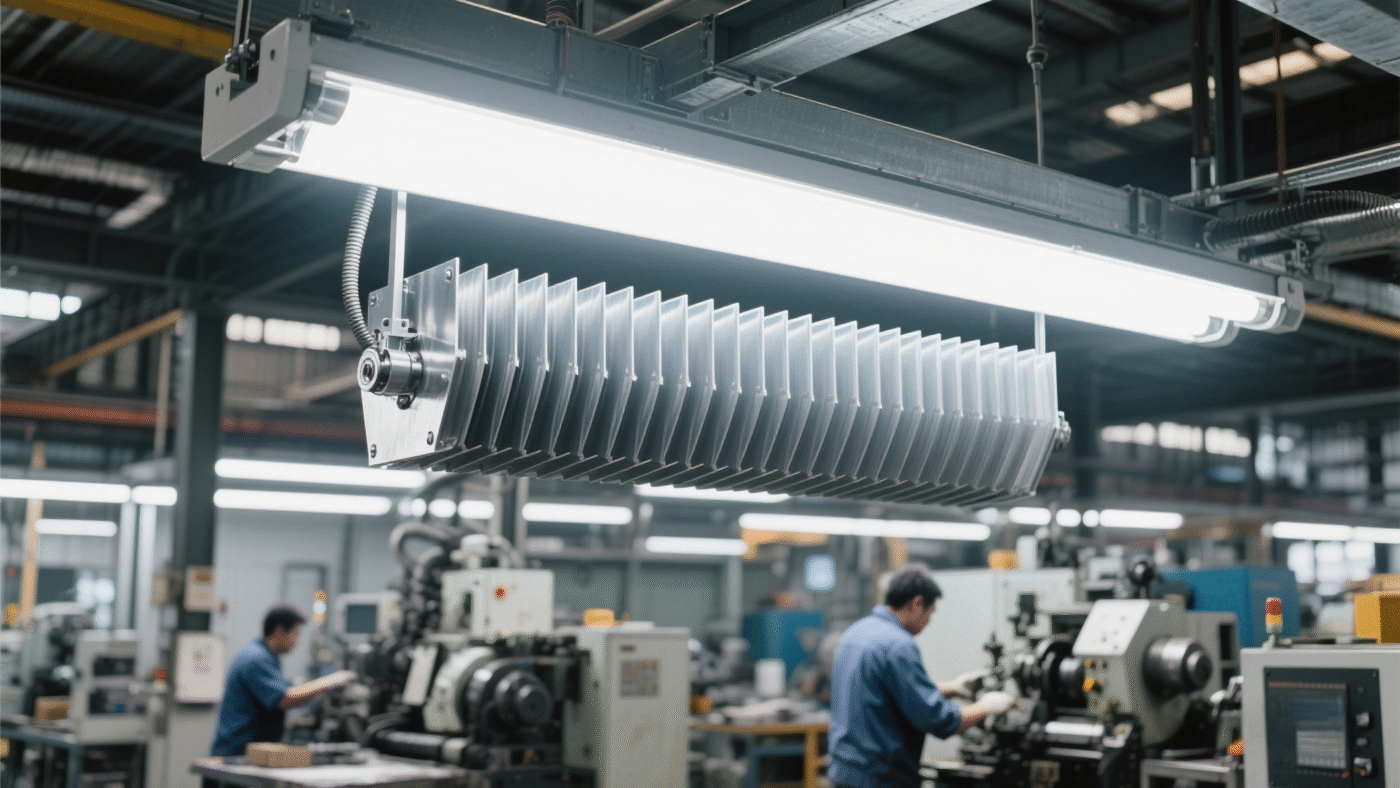

(1) Heat Sink Fins for High-Power Lighting

In industrial and high-power luminaires, extruded aluminum heat sink fins are vital for thermal management. By expanding surface area, they accelerate heat dissipation, ensuring stable operation in high-temperature environments.

(2) Versatile Lamp Shade Frames

Aluminum profiles form the backbone of lamp shade frames, providing structural support while leveraging their thermal and electrical conductivity to prevent heat buildup and static accumulation. Compatible with glass, plastic, and other materials, they enable diverse lighting effects and styles.

5. Driving Innovation and Sustainability

Extruded aluminum profiles are not just functional—they propel innovation. Their recyclability aligns with global sustainability goals, reducing the carbon footprint of lighting systems. Advanced extrusion technologies continue to push boundaries, enabling thinner walls, tighter tolerances, and integration with smart lighting solutions.

Conclusion

From enhancing thermal performance to enabling bold designs, extruded aluminum profiles are deeply embedded in the lighting industry’s evolution. They ensure reliability in outdoor settings, optimize energy efficiency, and support cutting-edge applications—from urban infrastructure to artistic displays. As the industry advances toward smarter, greener solutions, aluminum extrusion technology will remain a cornerstone, illuminating new possibilities and driving high-quality development across the globe.