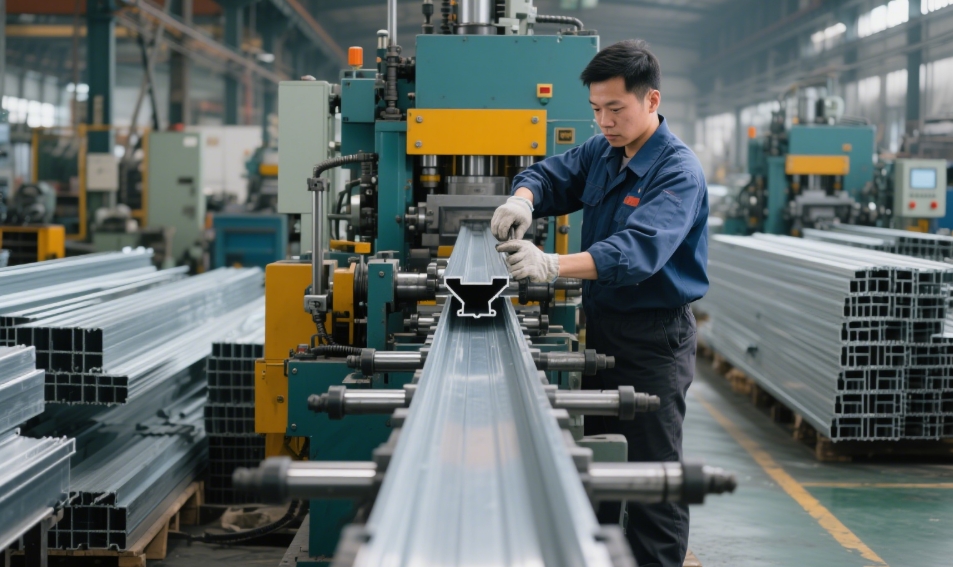

In the industrial manufacturing field, aluminum profile extrusion plays a crucial role in creating high – quality and customized products. As shown in the image, these customized aluminum extrusion profiles offer a wide range of shapes and sizes to meet diverse project requirements.

Diverse Shapes and Sizes

The picture presents an array of aluminum profile extrusion products with different geometries. From simple rectangular bars to complex multi – cavity profiles, there is a vast selection available. This diversity allows designers and engineers to bring their unique ideas to life. Whether it’s for building structures, machinery frames, or decorative elements, these profiles can be tailored to fit specific needs.

Anodized Finish

Many of the custom aluminum extrusion profiles in the image have an anodized finish. Anodizing not only enhances the corrosion resistance of the aluminum but also provides a smooth and attractive surface. It can also be colored to match different aesthetic preferences, adding a touch of style to industrial applications.

Customization Capability

One of the key advantages of aluminum profile extrusion is its high degree of customization. This means that customers can get profiles with specific dimensions, surface treatments, and mechanical properties according to their project requirements.

Industrial Applications

These aluminum profile extrusion products are widely used in various industries. In the construction industry, they can be used for window frames, curtain walls, and handrails. In the machinery industry, they serve as structural components and guides. Their lightweight yet strong nature makes them a popular choice for many applications.

In conclusion, if you’re looking for a reliable and versatile material for your projects, consider customized aluminum extrusion profiles. With their diverse shapes, anodized finishes, and customization capabilities, they are sure to meet your needs and enhance the quality of your products.