Introduction

Renowned for their lightweight properties, high strength, and corrosion resistance, aluminum alloys have long been indispensable in aerospace manufacturing. As aviation technology advances rapidly, demands for aluminum alloy performance grow increasingly stringent, driving innovations in composition, processing, and applications. This article explores key trends shaping the evolution of aerospace-grade aluminum alloys.

1. Continuous Optimization of Alloy Composition

(1) Main Alloying Elements

Modern aluminum alloys are evolving toward higher alloying levels, with increased Zn, reduced Cu, and optimized Zn/Mg and Cu/Mg ratios. In 7XXX-series alloys, elevating Zn and Mg content promotes the precipitation of η-phase (MgZn₂) strengthening particles, boosting mechanical strength. While copper enhances castability, its reduction improves overall alloy performance.

(2) Micro-Alloying Innovations

-

Zr Addition: In third-gen alloys like 7050, zirconium refines as-cast grains. Post-heat treatment, Al₃Zr dispersoids provide dual grain refinement and dispersion strengthening.

-

Rare Earth Elements: Scandium (Sc) significantly enhances microstructure refinement. Co-adding Sc and Zr further improves thermal stability. To reduce costs, Er is being studied as a Sc alternative, with nano-scale Al₃Er precipitates pinning dislocations and subgrain boundaries, elevating strength and recrystallization resistance.

-

Mn, Ti, Cr: Research continues on single or combined additions of these elements to tailor properties.

2. Demanding Performance Requirements

(1) Ultra-High Strength & Toughness

New-generation aluminum alloys like 7150-T77 and 7055-T77 achieve breakthroughs in strength (exceeding 600 MPa) while maintaining high fracture toughness and stress corrosion resistance. Damage-tolerant alloys such as 2E12 are also emerging.

(2) Enhanced Corrosion & Fatigue Resistance

Process and compositional refinements reduce corrosion risks in harsh environments (e.g., humidity, salt spray) and mitigate fatigue failure in cyclic loading.

3. Revolutionary Manufacturing Processes

(1) Integrated Forming Technologies

Large-scale aluminum alloy components are now machined via CNC milling from monolithic blocks, replacing traditional assemblies. This approach reduces weight by 15–20%, enhances reliability, and cuts assembly costs. Applications include integral wing panels in aircraft.

(2) Advanced Processing Techniques

-

Casting & Rolling: Thin-strip continuous casting and rolling improve uniformity.

-

Novel Methods: Electromagnetic casting, rapid solidification, rheocasting, and spray deposition enable precise microstructure control.

-

Additive Manufacturing: 3D printing technology is unlocking new possibilities for high-strength aluminum alloys in complex geometries, supported by cryogenic processing to enhance ductility.

4. Innovative Product Structures

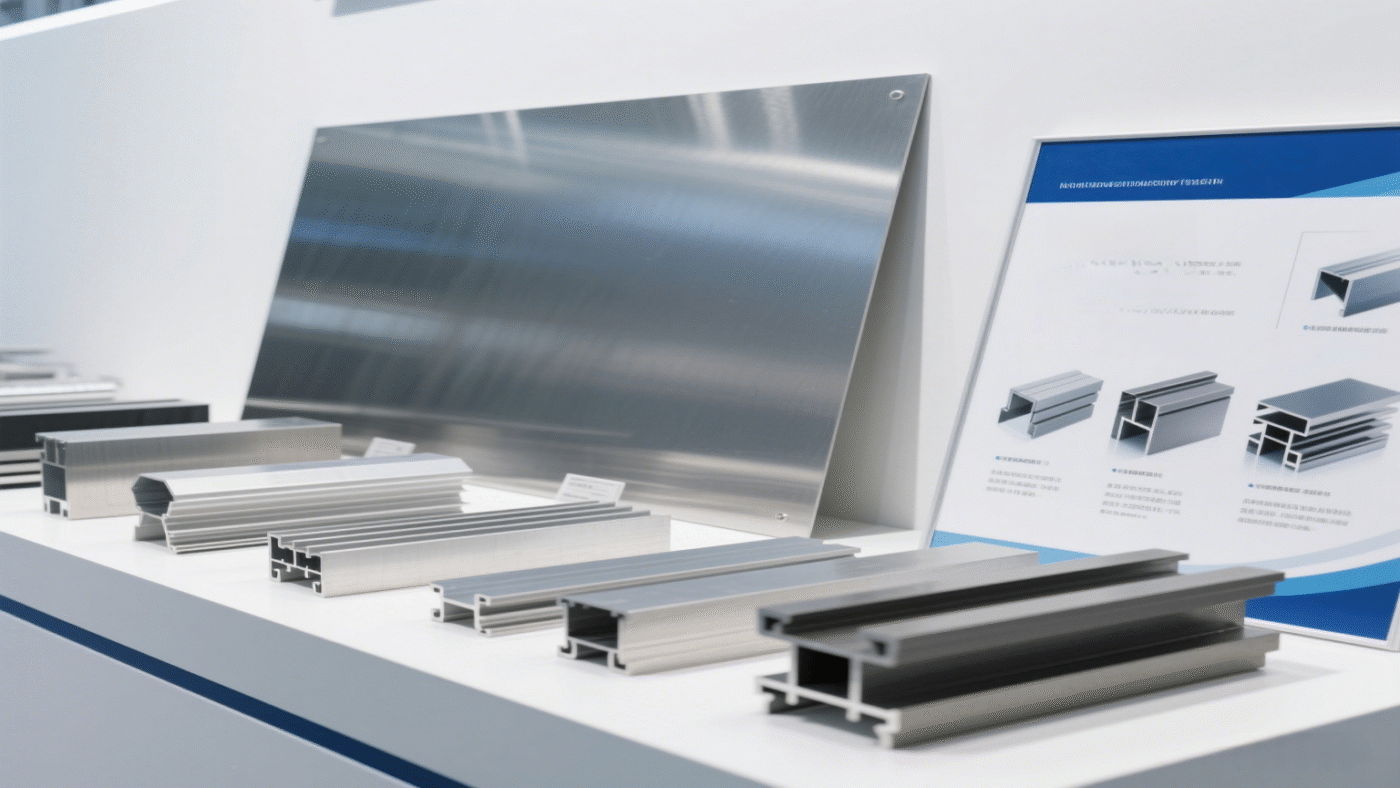

(1) Large-Scale Components

Demand grows for thick aluminum alloy plates (>150 mm) and extruded profiles with uniform properties across sections, critical for aircraft structural parts like fuselage frames.

(2) Next-Gen Materials

-

Al-Li Alloys: Lithium reduces density by 3–5% while increasing stiffness.

-

Aluminum Matrix Composites (AMCs): Reinforced with ceramics or carbon fibers, AMCs offer superior wear and thermal resistance.

-

Superplastic Forming Alloys: Enable complex shapes with high precision for engine components.

5. Future Directions: Intelligence & Sustainability

Smart aluminum alloys embedded with sensors for real-time health monitoring are under development. Meanwhile, recycling technologies and low-carbon smelting processes align with aviation’s sustainability goals.

Conclusion

Aluminum alloy materials are advancing toward high performance, diversification, and intelligence, meeting the aerospace industry’s evolving needs. From ultra-strong 7XXX-series alloys to 3D-printed components, these innovations propel aviation technology to new heights—lighter, safer, and more efficient than ever before. As R&D accelerates, aluminum alloys will remain the backbone of aerospace manufacturing, driving breakthroughs in next-gen aircraft design.